Tech News

PHNX Materials found a way to decarbonize concrete using dirty coal waste

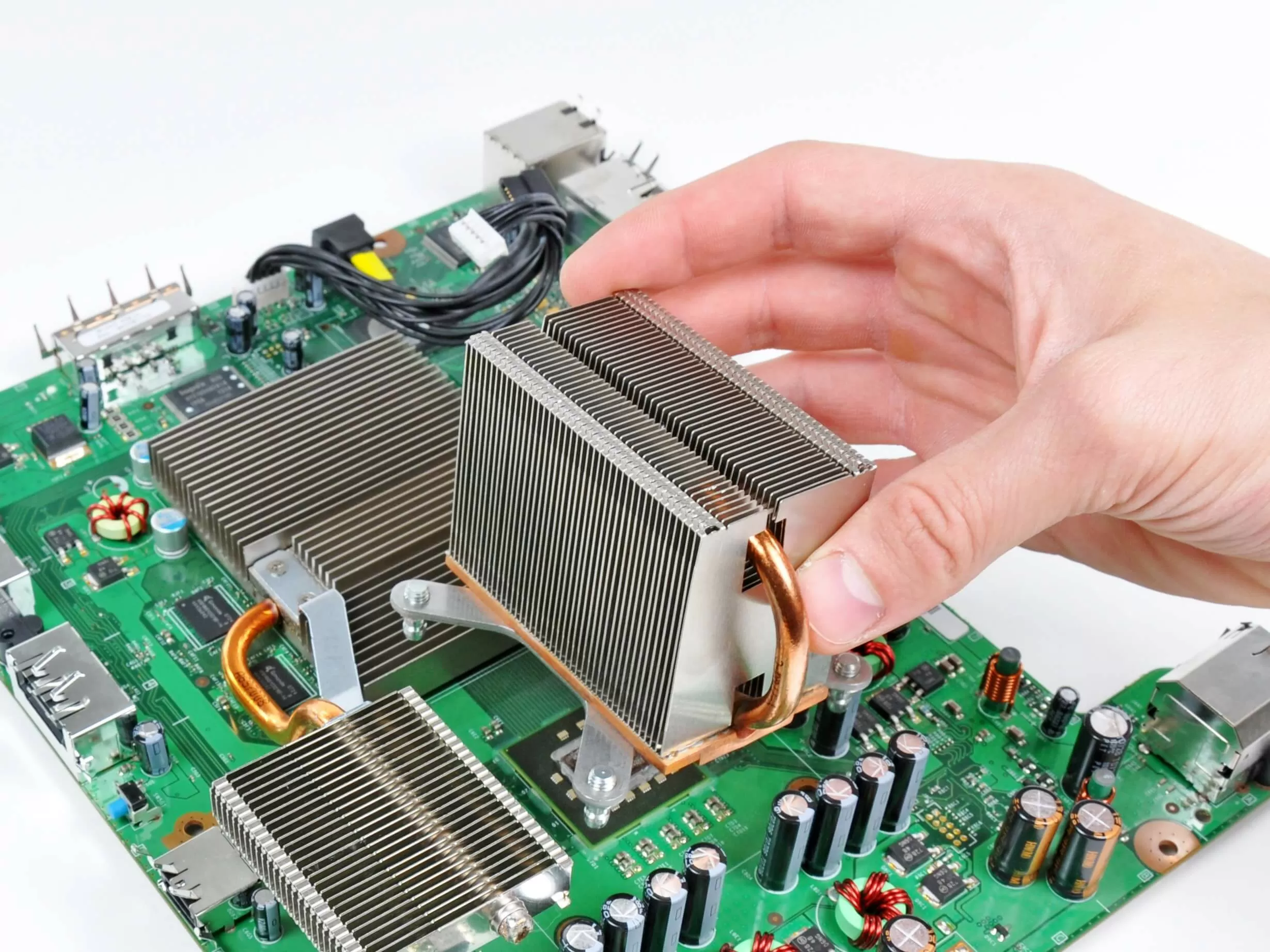

Coal-fired power plants have caused significant harm over the years, contributing to issues such as climate change, acid rain, and various health problems. However, there is a silver lining in the form of fly ash, a byproduct that can help reduce the carbon footprint of concrete production.

PHNX Materials, a startup company, has developed a process to purify fly ash by removing impurities like sulfur and aluminum. This purified fly ash can then be used as a substitute for up to 30% of cement in concrete, offering environmental benefits and creating a new source of valuable materials.

The company recently secured a $2.5 million seed funding round, signaling growing interest in sustainable concrete solutions. Fly ash has a long history of use in concrete, with its ability to improve stability and durability in construction projects.

As coal-fired power plants close down, the availability of fly ash has decreased, leading to a shortage in the market. This has prompted companies to reduce the amount of fly ash in their concrete mixes, impacting both the quality and environmental impact of the final product.

PHNX’s innovative approach not only addresses the fly ash shortage but also offers a more sustainable option for the concrete industry. By extracting valuable elements from fly ash and selling them to various industries, the company aims to decarbonize the sector and create a circular economy for these materials.

With a focus on sustainability and efficiency, PHNX is poised to make a significant impact on the concrete industry and contribute to a greener future.

-

Breaking News2 years ago

Breaking News2 years agoCroatia to reintroduce compulsory military draft as regional tensions soar

-

Destination1 year ago

Destination1 year agoSingapore Airlines CEO set to join board of Air India, BA News, BA

-

Gadgets1 year ago

Gadgets1 year agoSupernatural Season 16 Revival News, Cast, Plot and Release Date

-

Productivity2 years ago

Productivity2 years agoHow Your Contact Center Can Become A Customer Engagement Center

-

Tech News2 years ago

Tech News2 years agoBangladeshi police agents accused of selling citizens’ personal information on Telegram

-

Gadgets10 months ago

Gadgets10 months agoGoogle Pixel 9 Pro vs Samsung Galaxy S25 Ultra: Camera Comparison Review

-

Gaming2 years ago

Gaming2 years agoThe Criterion Collection announces November 2024 releases, Seven Samurai 4K and more

-

Gadgets10 months ago

Gadgets10 months agoFallout Season 2 Potential Release Date, Cast, Plot and News