Motivation

Packed Bed Fume Scrubbers: How They Work and Their Advantages

Packed bed fume scrubbers, also known as packed bed tower scrubbers, are essential equipment used in industrial and manufacturing settings to control and treat harmful gases and pollutants. These devices ensure compliance with environmental regulations by removing contaminants from exhaust streams. This article will explore how a packed bed fume scrubber functions and highlight its key advantages.

How Packed Bed Fume Scrubbers Work

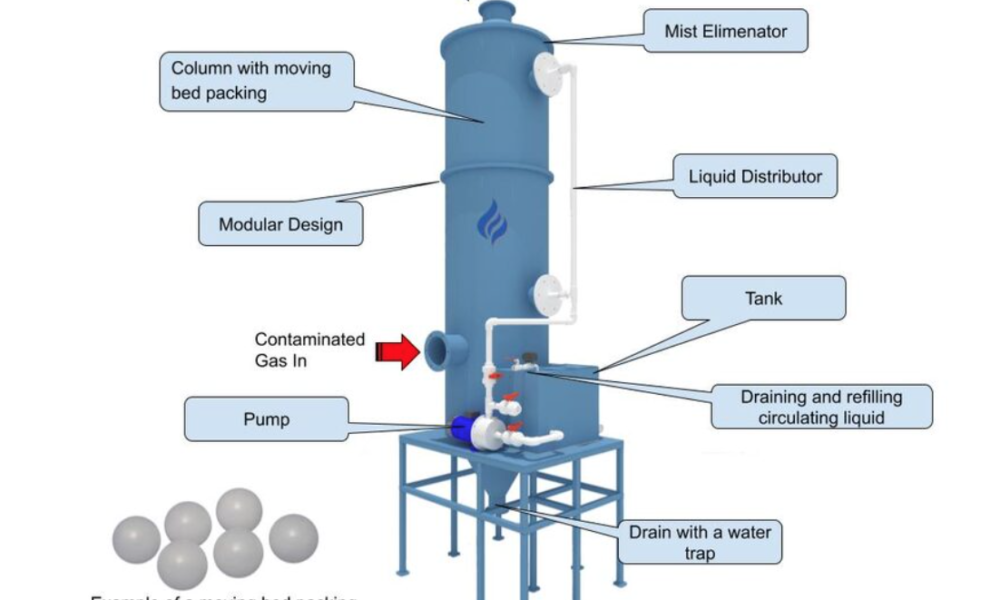

A packed bed fume scrubber operates using a packed bed of media within a vertical tower, providing an effective mechanism for gas-liquid contact. Here is a step-by-step explanation of their working process:

- Contaminated Gas Inlet: The polluted air or gas stream enters the packed bed tower scrubber through an inlet at the bottom of the unit.

- Liquid Distribution: A scrubbing liquid, typically water or a chemical solution, is evenly distributed over the packing material. This liquid is introduced from the top of the scrubber, creating a counterflow system where the gas flows upward while the liquid flows downward.

- Gas-Liquid Contact: The contaminated gas passes through the packed bed, where it interacts with the scrubbing liquid. The packing material in the tower maximizes surface area for effective contact between the gas and the liquid, promoting absorption or chemical reactions to neutralize contaminants.

- Pollutant Removal: As the gas moves through the packed bed, harmful compounds are absorbed or neutralized by the scrubbing liquid. Depending on the application, chemical reactions may occur, converting harmful gases into less harmful compounds.

- Cleaned Gas Discharge: The treated gas, now free of contaminants, is discharged through an outlet at the top of the packed bed fume scrubber.

- Liquid Recirculation: The scrubbing liquid is collected at the bottom of the scrubber and can be recirculated or treated before reuse, depending on the level of contamination.

Advantages of Packed Bed Fume Scrubbers

Packed bed fume scrubbers offer several benefits for industrial and manufacturing applications, making them a preferred choice for emission control. Some key advantages include:

- High Efficiency in Pollutant Removal: These scrubbers are highly effective in removing a wide range of pollutants, including acidic gases, odors, and volatile organic compounds (VOCs).

- Customizable Design: The structure and packing material can be customized based on the specific type of gas being treated.

- Corrosion Resistance: Constructed using materials resistant to corrosion, ensuring longevity in harsh industrial environments.

- Low Operational Costs: Require minimal maintenance, leading to lower operational costs over time.

- Scalable for Large Applications: Can be scaled up to accommodate large gas flow rates.

- Compliance with Environmental Standards: Help industries comply with stringent environmental regulations.

Applications of Packed Bed Fume Scrubbers

Packed bed fume scrubbers are versatile and suited for industries that generate harmful gases or odors. Common applications include:

- Chemical Processing Plants: Effective in treating hazardous gases like hydrogen chloride (HCl), sulfur dioxide (SO₂), and ammonia (NH??).

- Metal Finishing and Electroplating: Useful for removing fumes from acid baths and other chemical processes.

- Pharmaceutical Manufacturing: Helps eliminate harmful vapors generated during the production process.

Conclusion

Packed bed fume scrubbers are vital for industries seeking to control air pollution and adhere to environmental regulations. With their efficiency in removing contaminants and adaptability for various industrial needs, they provide a reliable solution for emission control. Their corrosion-resistant construction, low operational costs, and scalability make them a long-term investment for cleaner air and safer working environments.

-

Breaking News2 years ago

Breaking News2 years agoCroatia to reintroduce compulsory military draft as regional tensions soar

-

Destination1 year ago

Destination1 year agoSingapore Airlines CEO set to join board of Air India, BA News, BA

-

Gadgets1 year ago

Gadgets1 year agoSupernatural Season 16 Revival News, Cast, Plot and Release Date

-

Productivity2 years ago

Productivity2 years agoHow Your Contact Center Can Become A Customer Engagement Center

-

Tech News2 years ago

Tech News2 years agoBangladeshi police agents accused of selling citizens’ personal information on Telegram

-

Gadgets10 months ago

Gadgets10 months agoGoogle Pixel 9 Pro vs Samsung Galaxy S25 Ultra: Camera Comparison Review

-

Gaming2 years ago

Gaming2 years agoThe Criterion Collection announces November 2024 releases, Seven Samurai 4K and more

-

Gadgets10 months ago

Gadgets10 months agoFallout Season 2 Potential Release Date, Cast, Plot and News